Expert Molybdenum Machining Solutions for Precision Components

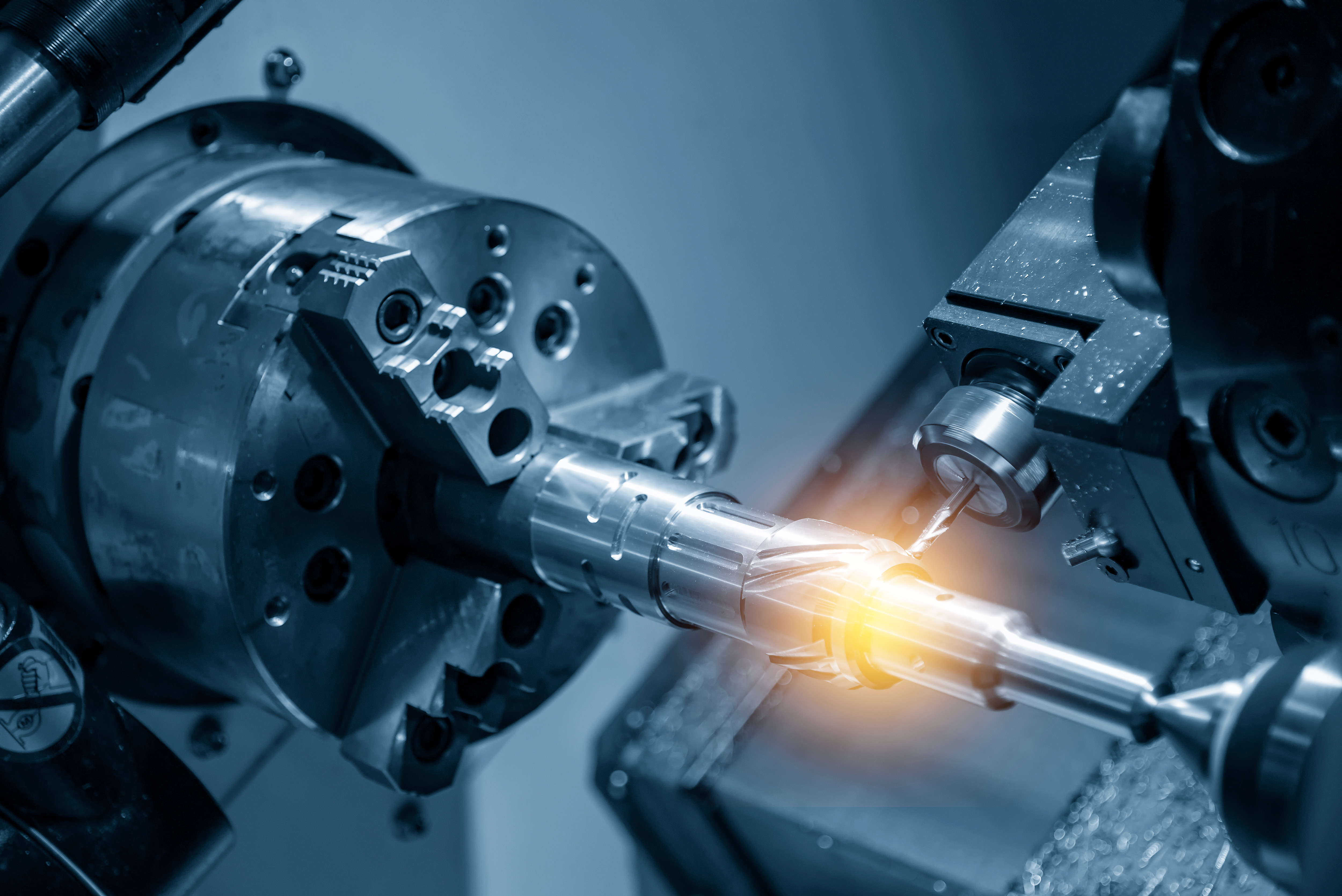

C&H Machine offers expert molybdenum machining, including precise molybdenum milling and molybdenum turning services, to deliver high-quality components for demanding applications. Our capabilities include EDM, CNC Milling, CNC Turning, Welding, and Assembly, ensuring precision and reliability in every part. From intricate designs to durable structures, we craft solutions that meet your exact needs while maintaining the highest industry standards. Our commitment to innovation and continuous improvement ensures exceptional service and support throughout the machining process.

Have questions about our molybdenum machining services? Contact us to discuss your project specifications or fill out a quote form, and we’ll start taking your project to the next level.

Advantages of Machining with Molybdenum

Molybdenum stands out for its exceptional qualities that make it an ideal choice for machining applications:

High-Temperature Strength: Molybdenum's remarkable melting point ensures the stability and integrity of components even under extreme heat conditions, making it indispensable for Aerospace and Power Generation applications. Its resilience to high temperatures guarantees the longevity and reliability of critical parts, contributing to the safety and efficiency of Aerospace Engines and Power Generation Systems.

High-Temperature Strength: Molybdenum's remarkable melting point ensures the stability and integrity of components even under extreme heat conditions, making it indispensable for Aerospace and Power Generation applications. Its resilience to high temperatures guarantees the longevity and reliability of critical parts, contributing to the safety and efficiency of Aerospace Engines and Power Generation Systems.- Superior Thermal Conductivity: With its excellent thermal conductivity, Molybdenum efficiently dissipates heat during machining processes, ensuring precise results, and preventing tool and workpiece overheating. This superior thermal conductivity enhances machining accuracy and prolongs tool life, resulting in high-quality components across various industries.

- Chemical Inertness: Molybdenum's remarkable resistance to corrosion and chemical reactivity makes it an ideal choice for applications in aggressive environments. Its unmatched durability ensures longevity and reliability, providing peace of mind in harsh operating conditions.

- Enhanced Machinability: Despite its inherent robustness, Molybdenum maintains excellent machinability using conventional methods, allowing for the creation of intricate designs and precise finishes. This enhanced machinability streamlines the Manufacturing Process, resulting in high-quality components with intricate geometries and tight tolerances.

Applications of Molybdenum Machined Parts

- Aerospace: We specialize in crafting critical components for aerospace applications, including aircraft engines, structures, and propulsion systems. Our expertise ensures the highest standards of precision, reliability, and performance, meeting the stringent requirements of the aerospace industry.

- Electronics: With our precision machining capabilities, we deliver superior quality components for the electronics sector. From semiconductor molds to connectors and electrical contacts, our precise machining ensures optimal functionality and reliability in electronic devices and systems.

- Medical Devices: Our precision machining plays a crucial role in manufacturing orthopedic implants, surgical instruments, and other biocompatible components for the medical industry. We adhere to strict quality standards to ensure the safety, efficacy, and longevity of medical devices, contributing to advancements in healthcare worldwide.

- Energy & Power Generation: In the Energy & Power Generation Sector, we produce high-quality parts for gas turbines, steam turbines, and nuclear reactors. Our precision machining ensures the efficiency, reliability, and safety of these critical components, supporting the global demand for sustainable energy solutions.

Quality Assurance and Inspection

As an AS9100:2016 Rev. D Certified and ISO9100 Compliant facility, we prioritize quality at every stage of the machining process. Our Inspection Department is equipped with CNC Smart Scope and other advanced testing devices ensures adherence to the highest standards and specifications.

Partner with C&H Machine for precision machining solutions with Molybdenum. Contact us today to discuss your project requirements!

Let's Talk

Have we caught your attention? Or are there any questions you still need answered? Fill in a RFQ, our Contact Form, or just give us a quick call and you will be connected immediately to one of our friendly staff. We look forward to meeting you!