Expert Copper & Brass Machining Services for Complex Parts

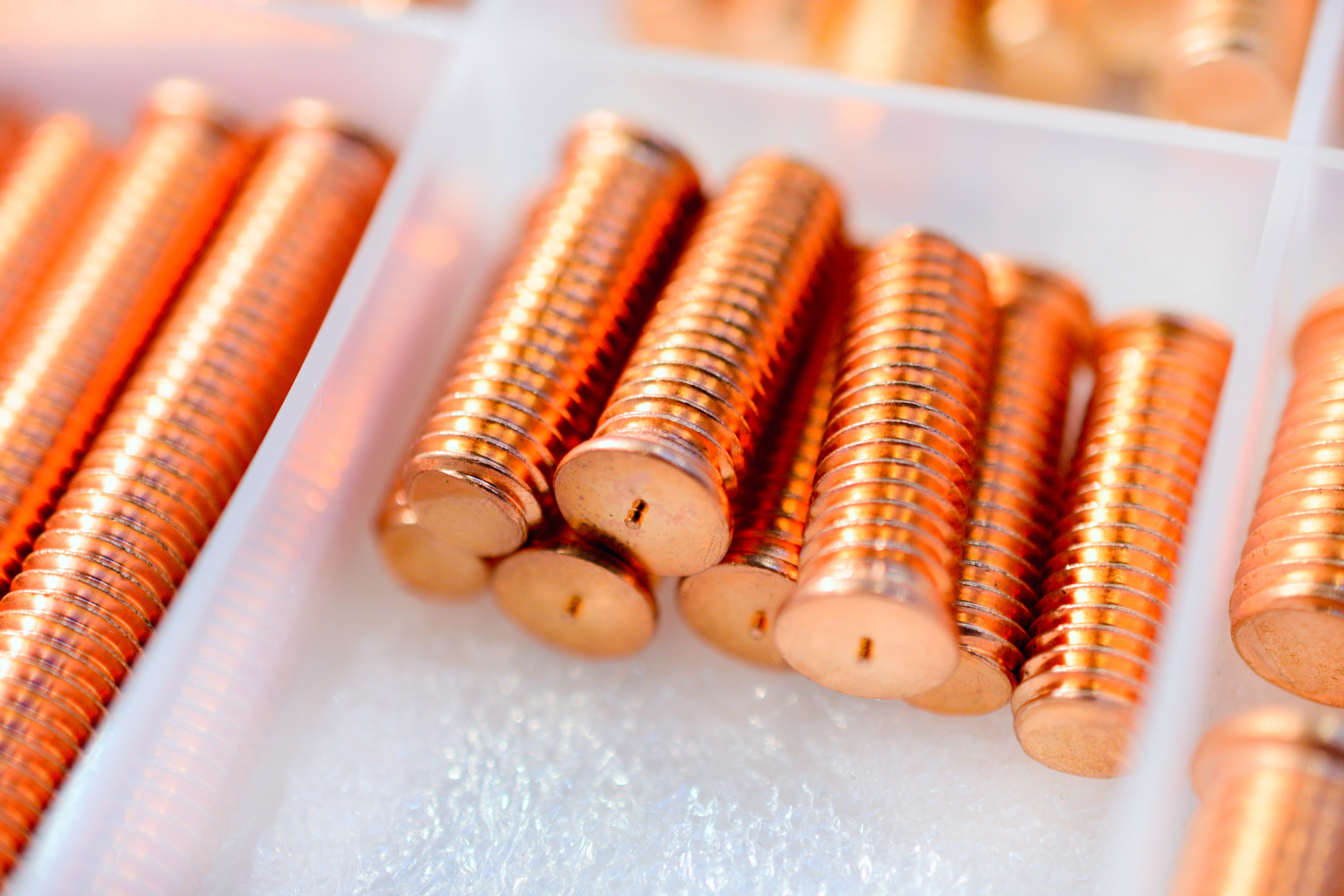

C&H Machine specializes in copper machining, copper milling, and copper turning, as well as brass machining, brass milling, and brass turning. With over 60 years of experience, we are experts in producing high-precision components for a range of industries, including aerospace, medical, electronics, and military defense. Our advanced technology and commitment to excellence allow us to meet the highest standards of quality, ensuring reliable, precision-crafted copper and brass components for your needs. Whether it’s intricate aerospace parts or high-performance electronics, we exceed client expectations with every project.

Have questions about our copper machining services or brass machining services? Contact us to discuss your project specifications or fill out a quote form, and we’ll start taking your project to the next level.

Advantages of Copper & Brass Machining:

Exceptional Conductivity: Brass and Copper are renowned for their excellent electrical and thermal conductivity properties, making them indispensable materials in industries where efficient heat dissipation and electrical conductivity are paramount.

Exceptional Conductivity: Brass and Copper are renowned for their excellent electrical and thermal conductivity properties, making them indispensable materials in industries where efficient heat dissipation and electrical conductivity are paramount. - Corrosion Resistance: Both Brass and Copper offer remarkable resistance to corrosion, ensuring longevity and reliability in demanding environments, such as aerospace and medical applications where exposure to harsh conditions is common. Historically brass has been renowned for its ability to retain its integrity over centuries of exposure.

- Machinability: Brass and Copper exhibit superb machinability characteristics, allowing for intricate designs and tight tolerances to be achieved. Our state-of-the-art CNC Milling and Turning capabilities ensure precise and efficient machining of Copper & Brass components to meet the most stringent specifications.

- Aesthetic Appeal: With their distinctive golden hue (in the case of Brass) and warm reddish-brown tones (in the case of Copper), these materials offer aesthetic appeal that is often sought after in various industries, including electronics and decorative applications.

Applications for Copper & Brass Machined Parts:

- Aerospace: Brass and Copper components play critical roles in Aerospace applications, including heat exchangers, and electrical connectors, thanks to their excellent conductivity.

- Medical: In medical devices and equipment, Brass and Copper are widely used for their biocompatibility, antimicrobial properties, and ability to withstand sterilization processes, making them ideal for surgical instruments, implants, and diagnostic equipment.

- Electronics: Brass and Copper are essential materials in the electronics industry, utilized in circuit boards, connectors, switches, and terminals due to their conductivity, corrosion resistance, and suitability for precision machining.

- Military/Defense: The rugged durability, corrosion resistance, and electrical conductivity of Brass and Copper make them indispensable in military and defense applications, including radar systems, ammunition components, and communication equipment.

Contact C&H Machine for Your Copper & Brass Machining Needs

At C&H Machine, we are committed to delivering precision machined Copper & Brass components that meet the highest quality standards. Leveraging our excellent machining capabilities and expertise, we ensure each component is crafted with meticulous attention to detail. Our dedication to excellence ensures that every project receives the utmost care and precision. With state-of-the-art equipment and rigorous inspection processes, we guarantee the reliability, performance, and durability of every Copper & Brass component we produce.

Partner with us for your Copper & Brass machining needs and experience excellence in precision machining. Contact us today to discuss your project requirements and discover how we can elevate your aerospace, medical, electronics, and military/defense applications.

Let's Talk

Have we caught your attention? Or are there any questions you still need answered? Fill in a RFQ, our Contact Form, or just give us a quick call and you will be connected immediately to one of our friendly staff. We look forward to meeting you!